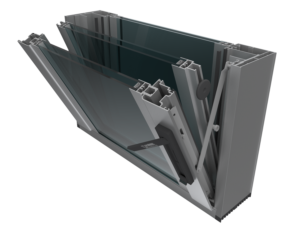

| Our aluminum profiles undergo a meticulous finishing process to enhance durability and aesthetic appeal. Initially, profiles are polished using specialized brushes and pastes to achieve the required smoothness and shine before entering the anodizing division. Once polished, the profiles undergo an electrochemical process that forms a protective aluminum oxide layer, strengthening them with thicknesses ranging from 8 to 25 microns, depending on their intended application. This process not only improves their visual appearance but also increases their resistance to corrosion caused by harsh weather conditions. The profiles are then sprayed with a specially formulated powder coating and subjected to a chemical pre-treatment to ensure optimal adhesion. Finally, they undergo a thermal curing process, achieving a uniform coating thickness of 60 to 80 microns for enhanced protection and longevity. |

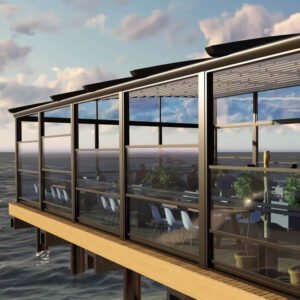

Fixed Glass Roof Systems

Elegant structures that provide natural lighting

and panoramic views