| Using advanced coating technology, we provide aluminum profiles with an authentic wood-like appearance while preserving their structural integrity. The process begins with precision polishing using brushes and specialized pastes to achieve a flawless surface before anodization. Following polishing, the profiles undergo an electrochemical anodizing process, forming a protective aluminum oxide layer with thicknesses ranging from 8 to 25 microns. This enhances their durability and resistance to environmental corrosion. Next, the anodized profiles are powder-coated with a base color, then covered with a high-quality decorative wood-effect film. The profiles are then thermally cured in specialized furnaces to ensure long-lasting resistance to varying weather conditions. Our wood-effect films come in a wide range of colors, textures, and woodgrain patterns, customizable to meet customer preferences and design requirements |

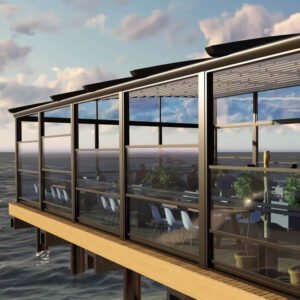

Fixed Glass Roof Systems

Elegant structures that provide natural lighting

and panoramic views